TESLA

I interned on the Chassis team at Tesla in the summers of 2018 and 2019. I worked at Tesla as a Mechanical Design Engineer (and then Senior Mechanical Design Engineer) between July 2020 and April 2024. I worked on brake systems for about a year before transitioning into the role I was hired for on the air suspension team.

2022-2024 Senior Mechanical Design Engineer

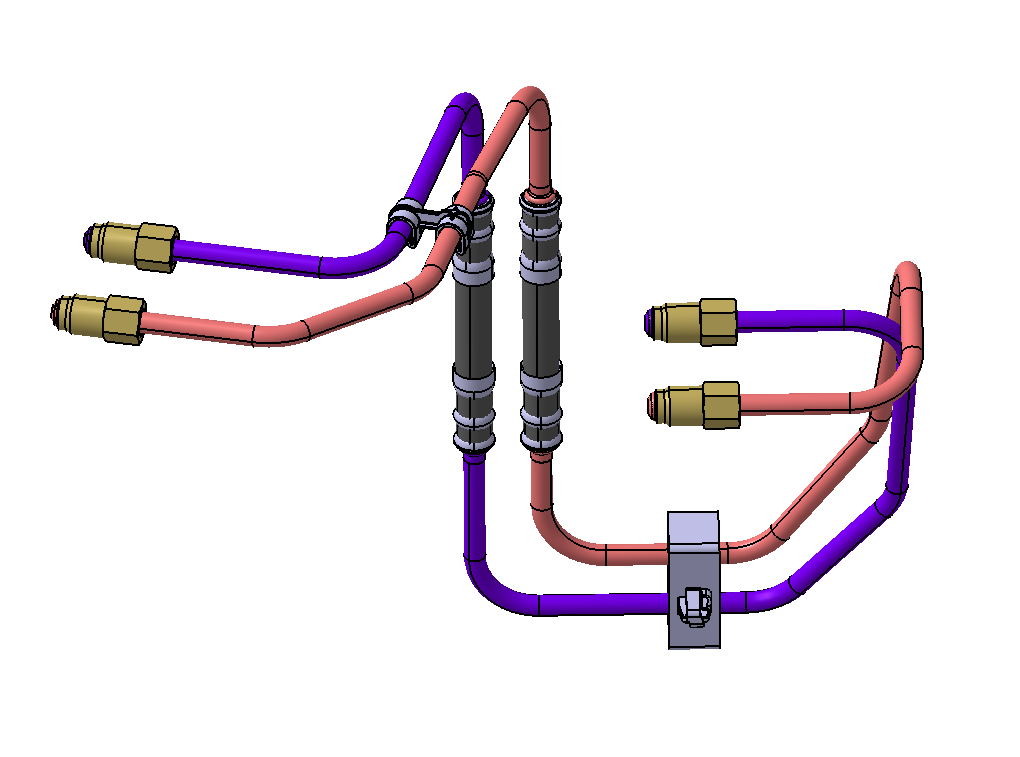

System owner for Cybertruck Air Suspension system

Determined targets and requirements for Air Suspension System based on product definition

Created and simulated various system configurations and layouts to achieve requirements

Owned 3D and 2D design for multiple system components including the air reservoir, air lines, valve block, air compressor isolation system, and multiple injection molded brackets

Delivered three rounds of prototype components off soft-tooling, and production level parts off production tooling with on-site support in Gigafactory Austin

Worked with process and equipment teams to determine line and assembly equipment design and specifications, delivered prototype line equipment

Created system, component, and process technical specifications and documentation

Deeply involved in integration and implementation of the hardware side of Cybertruck Wade Mode, which involves novel use of the air suspension system

Determined overall system functionality and component requirements with battery team - including adding an additional valve, three air lines, and additional mounting brackets

Listed on patent VWO2024243426 - BATTERY PRESSURIZATION SYSTEM

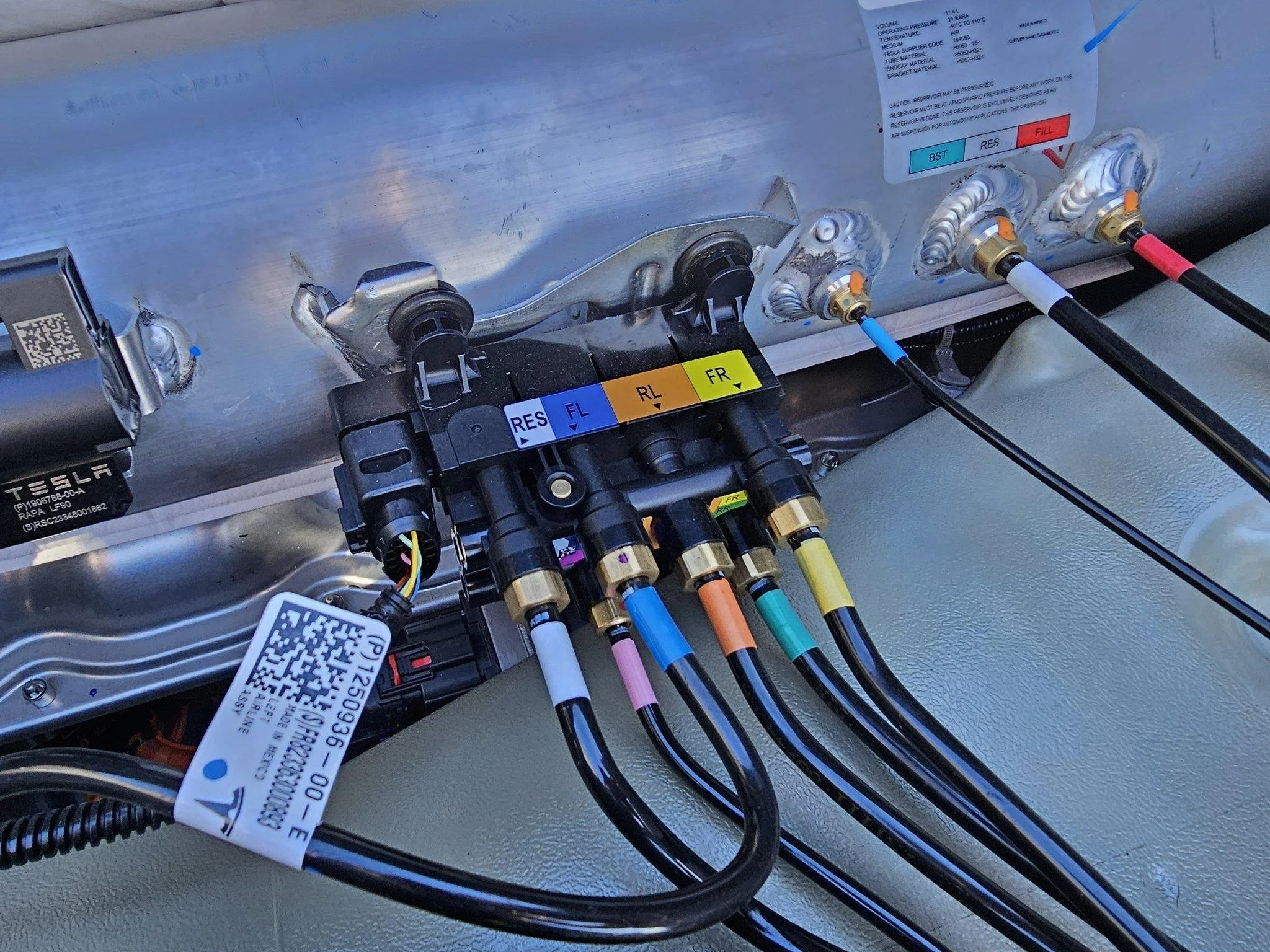

Cybetruck Air Suspension System overview from the 2024-2025 Cybertruck Parts Catalog

Images from cybertruckownersclub.com

2020-2022 Mechanical Design Engineer

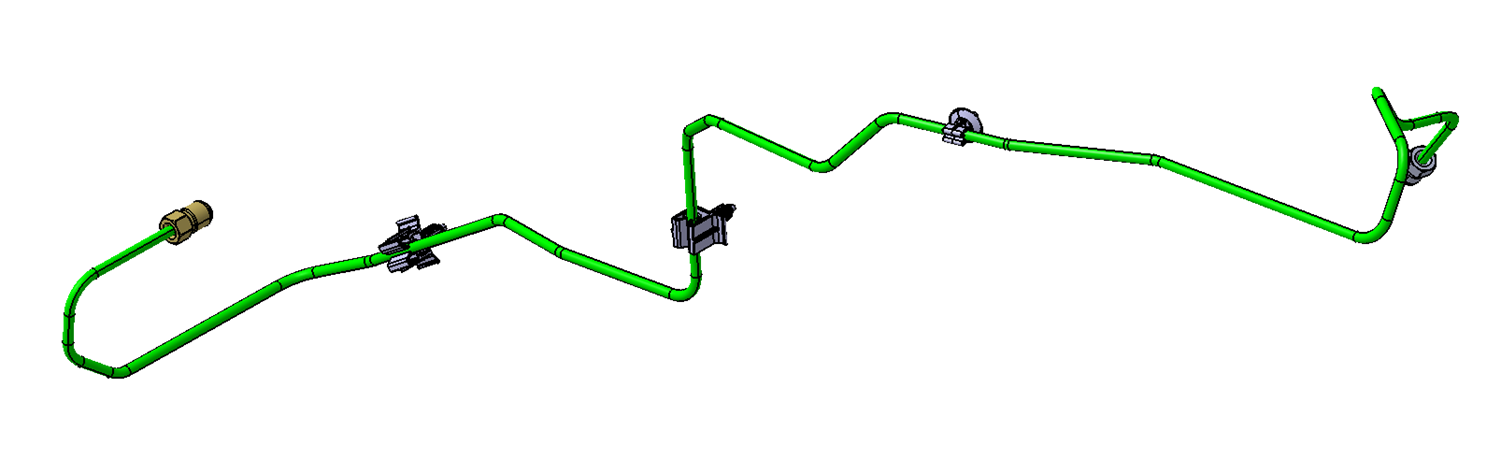

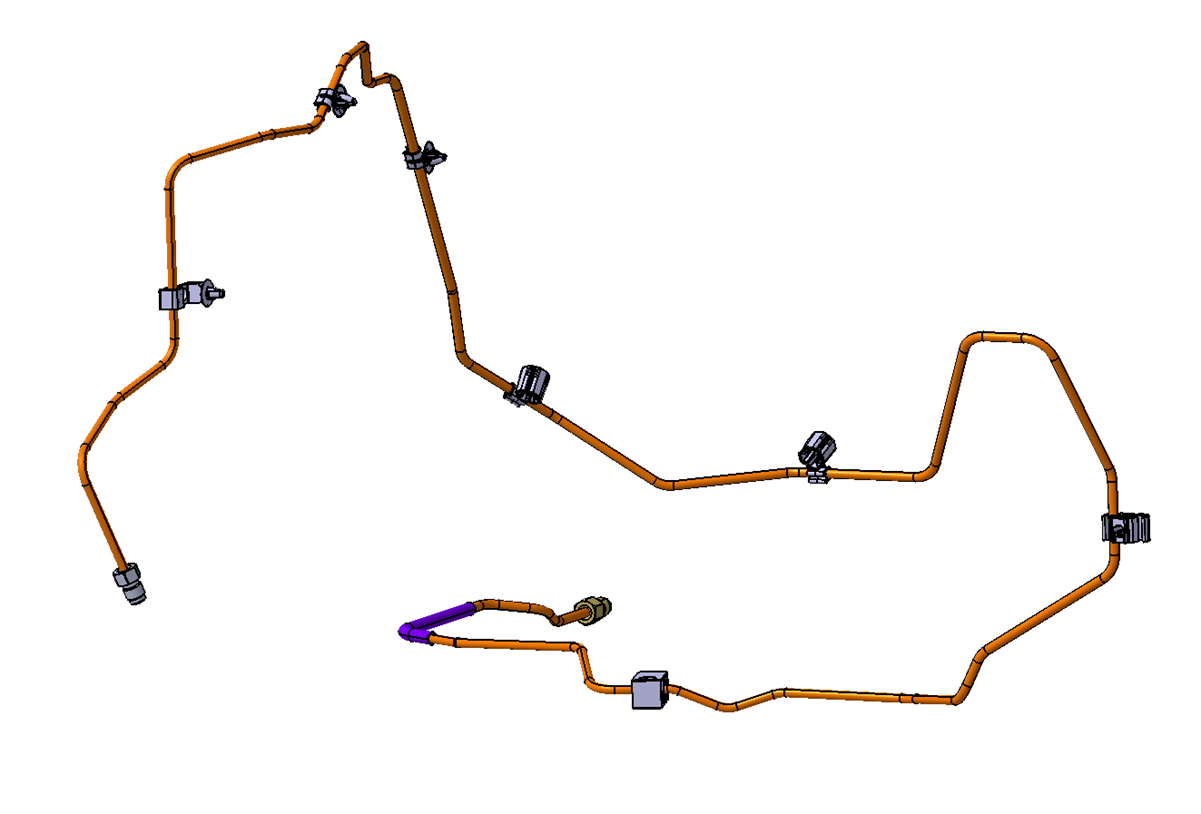

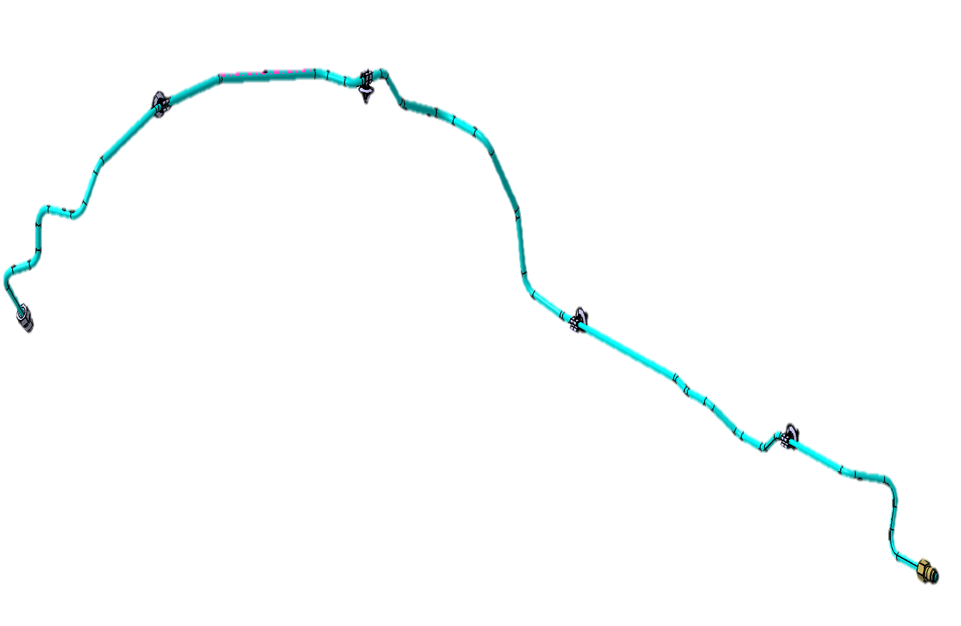

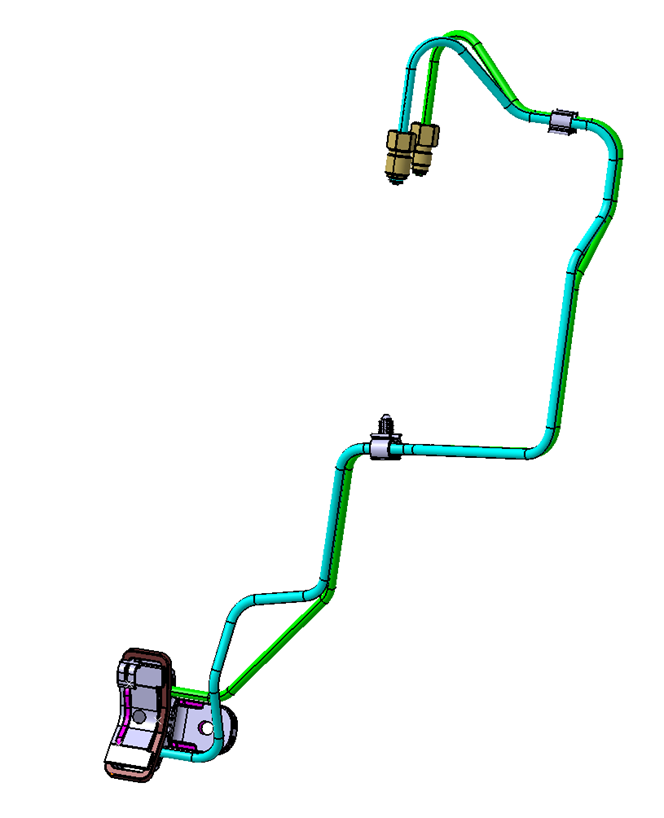

Component owner of hydraulic brake line distribution for Model S/X P2

Owned 3D and 2D designs for 10 pipe assemblies

Delivered and iterated on 3 rounds of pre-launch prototypes

Delivered parts off production tools and coordinated and approved Design and Production Validation (DVP) tests

Component owner of hydraulic control unit mounting bracket and assembly

Delivered soft-tool prototype and hard-tool production grade injection molded bracket

Owned fastener definition and torque specs

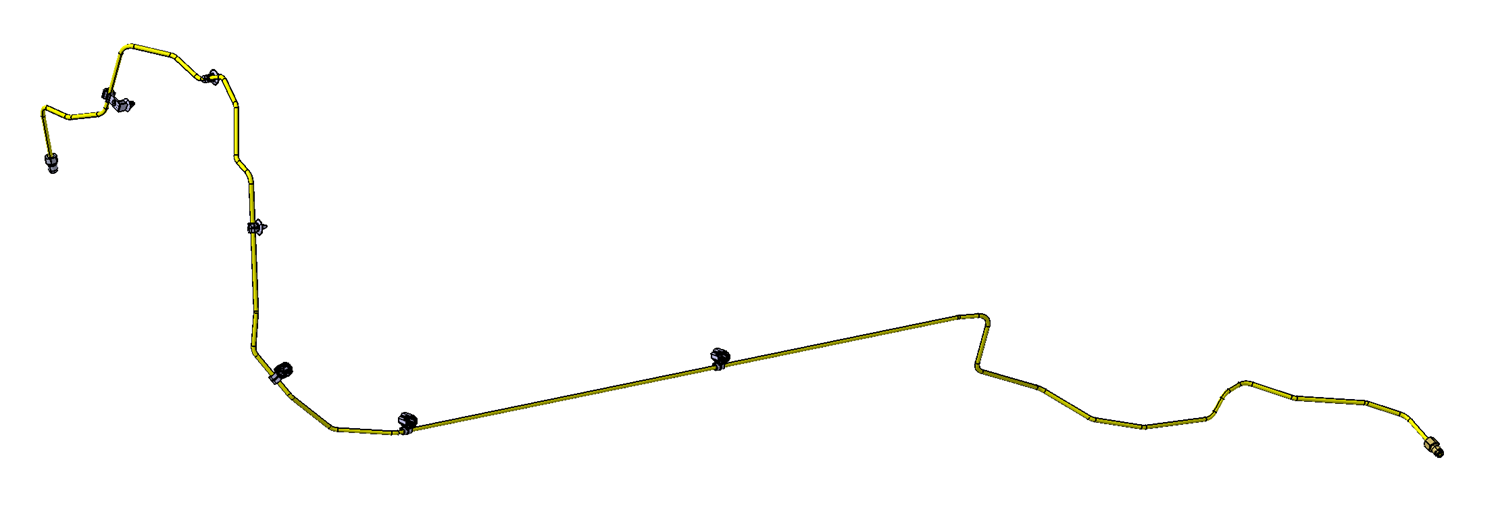

Component owner of hydraulic brake line distribution for Model Y Berlin

Owned 3D and 2D designs for 5 pipe assemblies

Piloted and validated new attachment strategy for pipe assemblies to as-cast features on gigacastings

Pictures of parts I owned from the 2021-2025 Model S Parts Catalog

Hydraulic Control Unit and bracket picture from TeslaShop.by

2018/2019 Internship

Designed and built fixtures, workstations, and worked on the line in GA4 - a quickly built assembly line to rapidly scale Model 3 production

Built automated test equipment for air compressor cycling characterization

Built air compressor test bench for Tesla Semi Air Compressor, simulated thermal characteristics